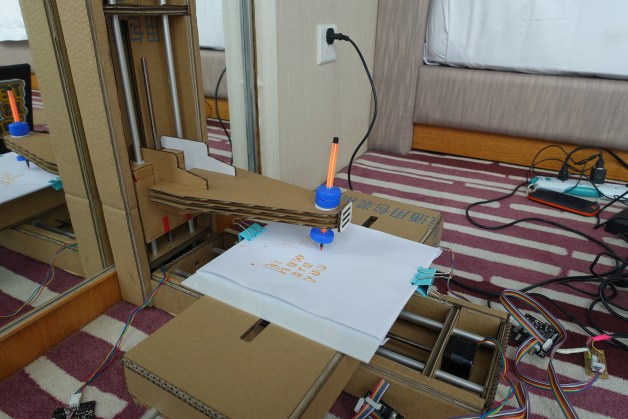

The drawing machine is based on “[modular] Machines that make: cardboard stages”, see details and plans here http://mtm.cba.mit.edu/machines/science

This work was started in collaboration with the MISIS university in Moscow and James Coleman, Ben Peters, Matt Hirsch, Ilan Moyer, and Nadya Peek in October 2013.

The drawing machine was made in a hotel in China Shenzhen using the locally sourced materials for maker’s week exhibition with helps from Nadya Peek + James Coleman + Calvin Zhong + Suzanne Magill.

Source Material

There are a lot of shopping and packing stores around China Shenzhen, it was easy to find cardboard boxes.

We were able to borrow a laser cutter for a couple hours.

We flatten and cut down the cardboard boxes to fit the laser cutter.

While James is figuring out the design (to fit the small size cardboard), Nadya is trying to figure out the best laser settings for cutting and scoring.

We packaged everything up and bring it back to our hotel for assemblage.

A little video about 華強北 Huaqiangbei, Shenzhen China

We glue the machine together on the hotel floor.

At the meantime, Nadya is testing and assembling the boards using “gestalt”.

https://github.com/nadya/pygestalt

Done! We have X, Y and Z

Back at the new lab, we could not find rulers so we made one with the laser cutter.

Here is the file for the ruler ruler_2.eps

We figured out the size of the arm that will be holding the pan.

Download the Pan Arm EPS here pan_arm.eps

Here we used an Apple iMac Box.

We made the pan holding mechanism out of bottle caps and a spring that we got from Huaqiangbei (华强北) market.

This place has EVERYTHING.

The machine has too much Inertia, it doesn’t move in a straight line, it has too much slack. The circles and squares drawings weren’t great.

I decided to glue the hex nut onto the lead screw so the box would be locked securely with the lead screw. This also makes it easier to assemble because you don’t need to fix the hex but when tightening the screw.

Done!

Time for demo.

Amazing team work!